|

Ningbo Yinzhou Intime Machinery Co,.Ltd

|

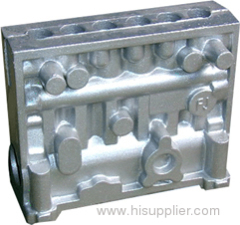

aluminum low pressure die casting

| Price: | 0.8~8.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Our castings foundry is specialized in manufacturing low pressure die casting parts, together with full capacity of CNC machining for casting

Thanks for your interesting with our Aluminum low pressure cast parts!!!

Low pressure die casting is a development of permanent mold process. The mold is installed on a sealed furnace containing molten metal. The riser tube connects the bottom of the mold to the molten metal bath. The chamber containing the molten metal is pressured (typically 20-100kPa), and the metal is forced up into the mold..Low pressure die casting part can perform with aluminum, zinc, copper alloys. Aluminum low pressure cast part offers high yields in excess of 90% as risers and runners are limited, also reducing fettling and trimming costs. Pore free castings are obtainable and machine size will limit the size of castings.

As a low pressure die casting parts designer, manufacturer, supplier in Ningbo China, Our aluminum casting foundry have more than 10 years experience with aluminum low pressure cast parts, sells the aluminum products all over the world. Our aluminum low pressure cast parts include aluminum low pressure cast part gear housing, aluminum low pressure cast part case, aluminum low pressure cast part pipe fittings, aluminum low pressure cast part cylinder housing, aluminum low pressure cast part engine piston, aluminum low pressure cast part cylinder parts, custom aluminum low pressure cast part, aluminum low pressure cast part wheel, cast aluminum parts, aluminum low pressure cast part cylinder head, aluminum low pressure cast part industry parts, aluminum low pressure cast part cylinder block, aluminum low pressure cast part cylinder cover, aluminum low pressure cast part pump body, aluminum low pressure cast part cylinder body, aluminum low pressure cast part valve body, aluminum low pressure cast part cylinder cover hood etc.

-Our low pressure die casting part foundry is specialized in manufacturing aluminum low pressure cast parts, together with full capacity of CNC machining for sand castings.

-Tooling design & manufacture for low pressure die casting part s

-Design capability for aluminum low pressure cast parts

Universal material for low pressure die casting part s: A356-T6, AlMg35, A413 etc.

-low pressure die casting part heat treatment with F, T1, T2, T4, T6, T5, T651

-excellent surface treatment technique for low pressure die casting part aluminum part include: alodine, anodizing, powder coating, plating, polishing, Nickel , chromate plating, zinc plating, gold finish, e-coating, wet painting, passivation etc.

Here below is the low pressure die casting part material comparison from different country:

| MATERIAL COMPARISON TABLE for ALUMIINUM LOW PRESSURE CASTING PARTS | |||||||

| China | USA | UK | France | Germany | Japan | ISO | |

| GB | ASTM | ANSI | BS | NF | DIN | JIS | |

| ZL101 | A03560 | 356 | \ | A-S7C | G-AlSi7Mg | AC4C | AlSi7Mg |

| ZL101A | A13560 | A356.0 | \ | \ | \ | \ | AlSi7MgA |

| ZL102 | A14130 | A413 | LM20 | A-S13 | G-AlSi12 | AC3A | AlSi12 |

| ZL104 | A03600 | A360 | LM9 | A-S9G | G-AlSi10Mg | AC4A | AlSi9Mg |

| ZL105 | A035500 | A355 | LM16 | \ | G-AlSi5Cu | AC4D | AlSi5Cu1Mg |

| ZL106 | A0328 | 328.0 | LM-24 | \ | G-ALSI8CU3 | AC4B | Al8Cu1Mg |

| ZL115 | \ | \ | \ | \ | \ | \ | Al5Zn1Mg |

| ZL116 | \ | \ | \ | \ | \ | \ | AlSi8MgBE |

| ZL201 | \ | \ | \ | A-U5GT | G-AlCu4TiMg | \ | AlCu4MgTi |

| ZL202 | A03600 | A360.0 | \ | A-U8S | \ | \ | AlCu10 |

| ZL203 | A029500 | 295.0 | \ | A-U5GT | G-AlCu4Ti | \ | Al-Cu4MgTi |

| ZL301 | A05200 | 520.0 | LM10 | G-AlMg10 | AC7B | AlMg10 | |

| ZL303 | \ | \ | \ | \ | \ | \ | AlMg5Si1 |

| ZL305 | \ | \ | \ | \ | \ | \ | AlMg8Zn1 |

| ZL401 | \ | \ | \ | \ | \ | \ | AlZn11Si7 |

| ZL402 | A071200 | 712.2 | \ | A-Z5C | \ | \ | AlZn6Mg |

-The delivery time we advise is reasonable and precision.

-we will produce some extra goods in our warehouse for stock each time, so anytime you need the delivery is possible.

-If the production meet resistance and may influence the delivery, we will inform to you in the first time. And we take the most efficent plan to solve the problem.

Any of your comments and queries will be highly appreciated. Thanks!

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Low Pressure Die Casting

Aluminum Pressure Die Casting

Low Pressure Casting

Pressure Die Casting

High Pressure Die Casting

Aluminium Pressure Die Casting

More>>